Hyundai Heavy Industries Power Systems has successfully carried out engineering projects related to Flue Gas Desulfurization for removal of sulfur oxides in exhaust gases since the early 2000s. Based on this experience, it has developed HHI-SCRUBBER, a scrubber for ships, to provide total solutions with design, manufacture, commissioning and guarantee.

Rigid R&D capability

Hyundai Heavy Industries Power systems carries out continuous research and development based on its unique R&D capabilities through technology partnership with Korea Shipbuilding & Offshore Engineering (KSOE)’s Advanced Research Center, and provides solutions optimized for individual project environments.

Outstanding productive capacity

Hyundai Heavy Industries Power systems has a production infrastructure that can produce up to 200 scrubbers annually, and skilled production professionals want to provide high-quality scrubbers to realize ship owner’s satisfaction.

Customer-centric service

Hyundai Heavy Industries Power systems proposes a professional scrubber retrofit solution through business partnership with Hyundai Global Service, an aftermarket company among Hyundai Heavy Industries Group affiliates, and has a global network to provide total service packages such as scrubber guarantee, repair, supply, and training.

SCRUBBERS SYSTEM

-

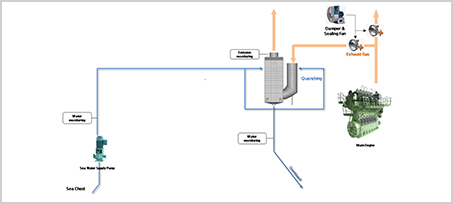

OPEN LOOP SYSTEM

The Open Loop System uses seawater as wash water, and alkalinity in seawater is used to remove SOx. The exhaust gas that enters the scrubber is controlled through the Bypass and Uptake dampers, and the drain water is discharged overboard. The exhaust gas and wash water are monitored continuously to comply with relevant emissions regulations. The Open Loop System is relatively simple and has low initial investment and operating costs, but may be limited by the operating environment, such as changes in seawater alkalinity or local water discharge regulations.

-

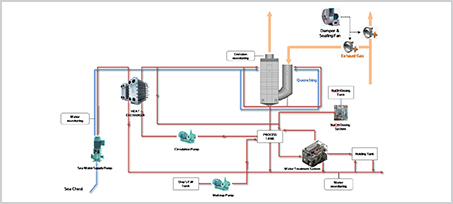

HYBRID SYSTEM

Hybrid System can be operated by switching from Open Loop Mode to Closed Loop Mode in the events of changes in seawater alkalinity or local water discharge regulations. Hybrid systems have a higher initial investment, but are not constrained by changes in the environment and can flexibly operate scrubbers, reducing operating costs compared to the Closed Loop System.

-

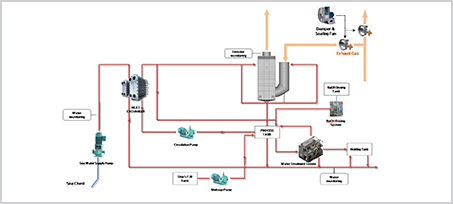

CLOSED LOOP SYSTEM

The Closed Loop System uses seawater or fresh water as wash water to remove SOx and is circulated continuously with the circulation pump, passing through process tank, heat exchanger and scrubber. The scrub water produced onboard ships, when scrubbing the exhaust gas for SOx, is stored in the holding tank in the non-discharge area and discharged overboard after out of that area. Closed Loop System requires additional equipment compared to Open Loop System, and initial investment and operational costs are high, but it can operate without restrictions in any of the world's oceans.

HHI-SCRUBBERSCRUBBERS OVERVIEW

HPS-02-SR-R

-

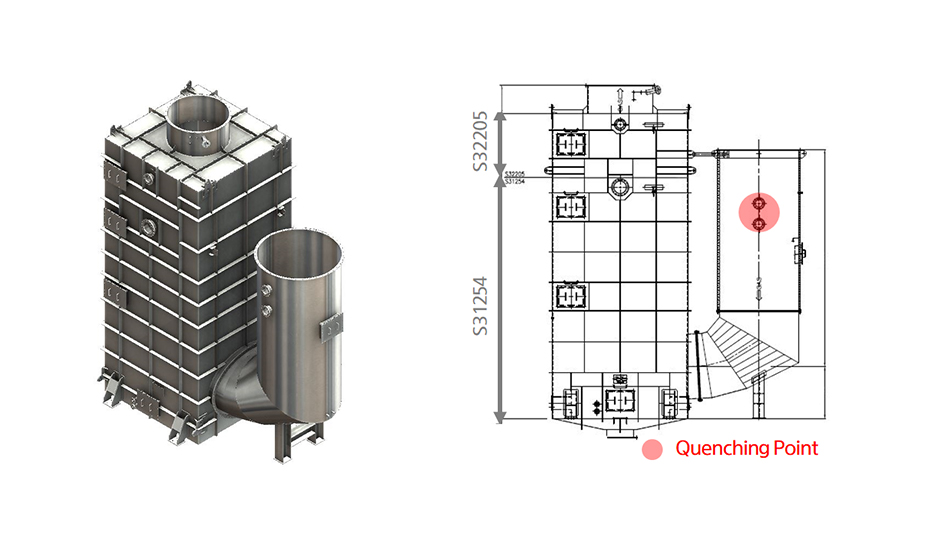

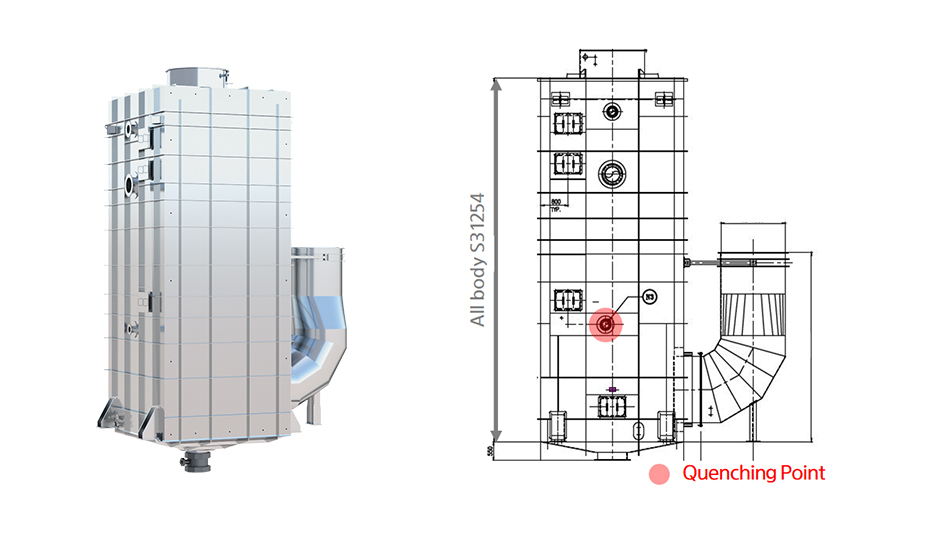

Rectangular-shaped Body Concept

Flexible layout with adjustment to the length and width

-

Application to casing material with S31254 and S32205

Durability with corrosion-resistant material

Cost-effective with material dualization

-

Application of quenching system in exhaust gas inlet

Low water consumption

Compact body

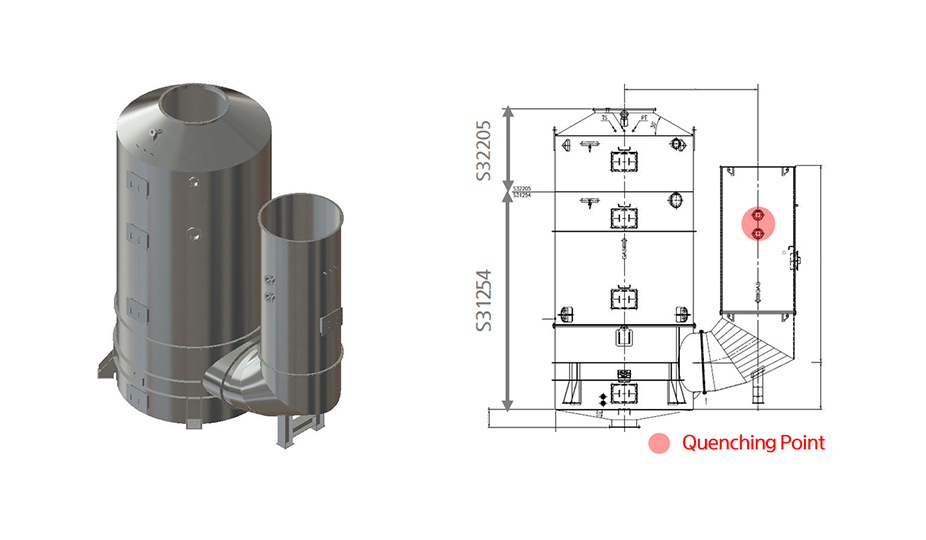

HPS-02-SR-C

-

Cylindrical-shaped Body Concept

Structural stability

-

Application to casing material with S31254 and S32205

Durability with corrosion-resistant material

Cost-effective with material dualization

-

Application of quenching system in exhaust gas inlet

Low water consumption

Compact body

HPS-01-TR-R

-

Rectangular-shaped Body Concept

Flexible layout with adjustment to the length and width

-

Application to casing material with S31254

Durability with corrosion-resistant material

Home

Home