Hyundai Heavy Industries Power Systems (HPS) provides reliable total solutions such as boiler performance improvement, retrofit & revamping engineering, increasing boiler availability to cope with performance degradation, fuel change and enhanced environmental regulation.

HPS is a boiler supplier with original technology not only diagnosis service for boiler operation data but also execute reverse engineering, retrofit & revamping engineering service. HPS can analyze boiler performance issue and related system then provide improved performance solution considering economic aspect.

HPS can supply optimized technology solution to reduce emission such as SOx, NOx, dust and etc., to meet the environmental regulation.

HPS is one of reliable engineering solution provider with boiler technology, will provide optimized engineering, retrofit & revamping, procurement and construction/commissioning services based on boiler performance design.

CS Business Area

-

01

Engineering service for Performance Diagnosis & Life Assessment

-

02

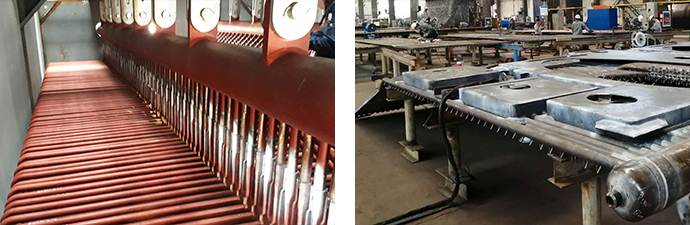

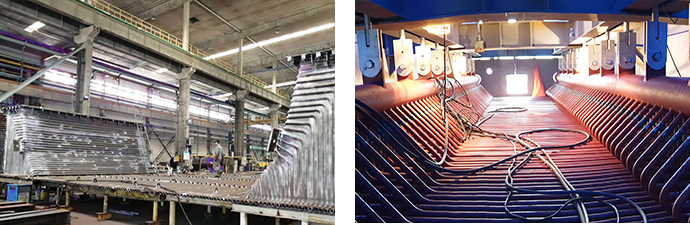

Performance improvement & Retrofit of Boiler furnace & convection pass

(E + P + C) -

03

Flue Gas Treatment System improvement & Retrofit

(E + P + C)

CS Value Chain

- Diagnosis

-

- Performance Diagnosis

- Life Assessment Preventive Inspections

- Root Cause Analysis

- Efficiency Evaluation

- Finding Solutions

-

- Reverse Engineering

- System Engineering

- Improvement Planning

- Efficiency Upgrade

- Energy Saving Solutions

- Retrofit & Revamping

- Rehabilitation

- Performance & Basic Design

-

- Thermal Performance Design

- CFD Analysis Thermal Structural Analysis

- CAPEX/OPEX Evaluation

- Detail Design

-

- Pressure/Non-Pressure Parts Design

- Detail Drawing

- Bill of Material

- Construction, Installation

-

- Demolition Plan

- Installation Plan

- Retrofit & Revamping Plan

- Commissionin

-

- Start-up

- Performance Test

Boiler Performing Category Value Chain

| Item | Boiler Performing Category | Remark | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Diagnosis | Solution | Retrofit Project |

O&M | |||||||

| Performance | Equipment | Reverse Eng | RCA | E | P | C | Operating Optimization |

Maintenance | ||

| Maintenance (Owner) |

|

|

|

|

|

|

|

|

|

EPC Outsourcing |

| Boiler Inspection Company |  |

|

|

|

|

|

|

|

|

Only conduct diagnosis |

| Repair Company |  |

|

|

|

|

|

|

|

|

Only conduct construction |

| Original Boiler technology supplier (Boiler Manufacture company) |

|

|

|

|

|

|

|

|

|

Non-CS organization |

| Hyundai Heavy Industries-Power Systems |  |

|

|

|

|

|

|

(Consulting) |

(Consulting) |

Execute project to comply customer requirements |

HPS can provide total solution such as boiler diagnosis, Performance improvement, operational optimization, Retrofit & Revamping, rehabilitation and etc.

HPS Provides Win-Win solution to owner through Customer Service (CS) projects.

Technology & Track Record

Technology

-

The solutions will be prepared by using the HPS’ own boiler technology and accumulated know-how and experiences in the following fields:

Application of various kinds of fuel : Coal, Petcoke, Pitch, Biomass etc.

Design, manufacturing, installation, commissioning and start-up.

Trouble shooting of boiler in operation

-

Hyundai Heavy Industry Power System (HPS) proposed solution covers the followings, subject to Client requirement:

Diagnosis of boiler operation

Root cause analysis

Customized solution for repair and/or upgrade of the boiler to improve the boiler performance and operation reliability.

Air pollution control system fit for actual boiler operation environment and requested emission level.

Track Record

| Description | Project | Period |

|---|---|---|

| Technical Consulting | 5 | 2018 ~ Presnet |

| Performance Diagnosis | 2 | |

| Retrofit & Revamping | 5 | |

| Total | 12 |

Track Records

| Year | Customer | Scope | Boiler Type | Steam (t/h) | Fuel | Remark |

|---|---|---|---|---|---|---|

| 2020 | GS CALTEX | E | HRSG | 60X1 | LNG | Boiler Retrofit & Flue Gas Treatment System Upgrade (SCR) |

| 2020 | KUMHO Petrochemical | E | CFBC/Gas Boiler | 290X1 / 60X1 | Coal/Tail | Boiler Retrofit & Flue Gas Treatment System Upgrade (SCR) |

| 2020 | LG Chemical | E | CFBC | 210X1 | Coal | Boiler Retrofit & Flue Gas Treatment System Upgrade (SCR) |

| 2019 | Hyundai Energy | E | CFBC | 350X1 | Coal | Performance Diagnosis |

| 2019 | Seetec | E | Oil Boiler | 150X1 | HFO | Performance Diagnosis |

| 2019 | Hanju #8 | E+P+C | CFBC | 250X1 | Coal | Boiler Retrofit (Boiler Capacity Increases, 190t/h→250t/h) Flue Gas Treatment System Upgrade (SCR) |

| 2019 | Hyundai Oil Bank #10 | E+P+C | CFBC | 330X1 | Petro coke | Boiler Retrofit (Boiler Capacity Increases, 330t/h→350t/h) |

| 2018 | Hyundai Oil Bank #9 | E+P+C | CFBC | 220X1 | Petro coke | Boiler Retrofit (Boiler Capacity Increases, 220t/h→240t/h) |

| 2006 | Hyundai Oil Bank #3 | E+P+C | CFBC | 120X1 | Petro coke | Boiler Retrofit (Boiler Capacity Increases, 94t/h→120t/h) |

Home

Home